Z-Axis Movements

The z-axis frequently stalls when moving upwards. Movements may fail to complete, and in some cases the z-axis may even stall and then begin moving in the opposite direction.

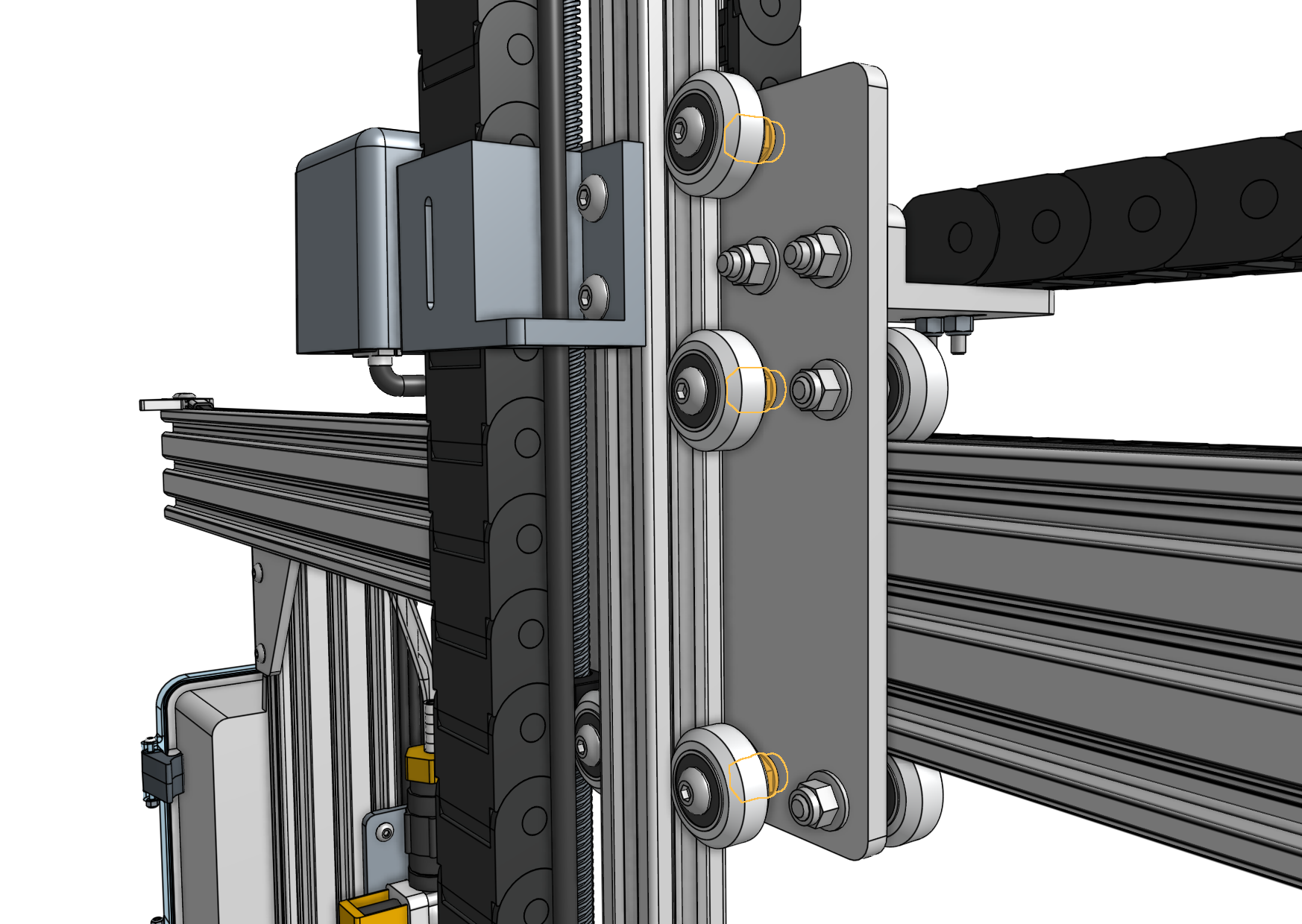

1. Check the z-axis eccentric spacers

Check the eccentric spacers on the cross-slide plate that are used to adjust the V-wheels that support the z-axis extrusion. If the eccentric spacers are adjusted too tightly, then they will exert too much force onto the z-axis extrusion which can make it difficult or impossible for the z-axis motor to raise the z-axis. With the FarmBot powered off, you should be able to rotate the leadscrew by hand without too much effort.

Refer to the eccentric spacer adjustment guide for more information.

2. Lubricate the leadscrew

Dust and debris can build up on the leadscrew and cause additional friction between the leadscrew and the leadscrew block. Clean the leadscrew with a rag and then use a dry graphite lubricant spray such as Jig-a-Loo Graphite Lubricant to coat the bottom 90% of the leadscrew surface with a fast drying coating of graphite. Leave the very top 10% unlubricated so that a sturdy grip can be applied to leadscrew by the coupler.

Apply enough graphite lubricant so that the hue of the screw looks significantly darker than the original silver metallic color. You should use enough graphite lubricant so that the screw should appear black or dark grey. This will create a slippery surface that reduces the resistance of movement through the leadscrew block and also may decrease any noise from the leadscrew.

Do not use oil, silicon, or lithium based lubricants

These types of lubricants will attract dust and gum up causing poor performance. Only graphite lubricants are acceptable.

Do not lubricate belts and pulleys

Applying a lubricant to the belts may cause a chemical reaction that rapidly degrades the belt material. Furthermore, a lubricant between the belts and pulleys may cause the teeth engagement to slip.

3. Adjust the z-axis speed and acceleration

Try lowering the z-axis MAX SPEED TOWARDS HOME by 10% and increasing the z-axis ACCELERATE FOR TOWARDS HOME by 25%. Because every FarmBot installation is a bit different, you will need to experiment to find the best values for you.

4. Turn off stall detection and adjust motor settings

If the troubleshooting steps above are not successful, try disabling stall detection for the z-axis. This will unlock slower motor speeds and higher motor current which can help the z-axis move more reliably.

- Disable z-axis STALL DETECTION

- Increase the z-axis MOTOR CURRENT to 100%

- Decrease the z-axis MIN SPEED, MAX SPEED, and MAX SPEED TOWARDS HOME

- Increase the z-axis ACCELERATE FOR and ACCELERATE FOR TOWARDS HOME

These changes will remove the ability for FarmBot to find axis length and find home along the z-axis. After implementing the changes, ensure you are not using the find home function for the z-axis in any of your sequences, such as in the boot sequence.

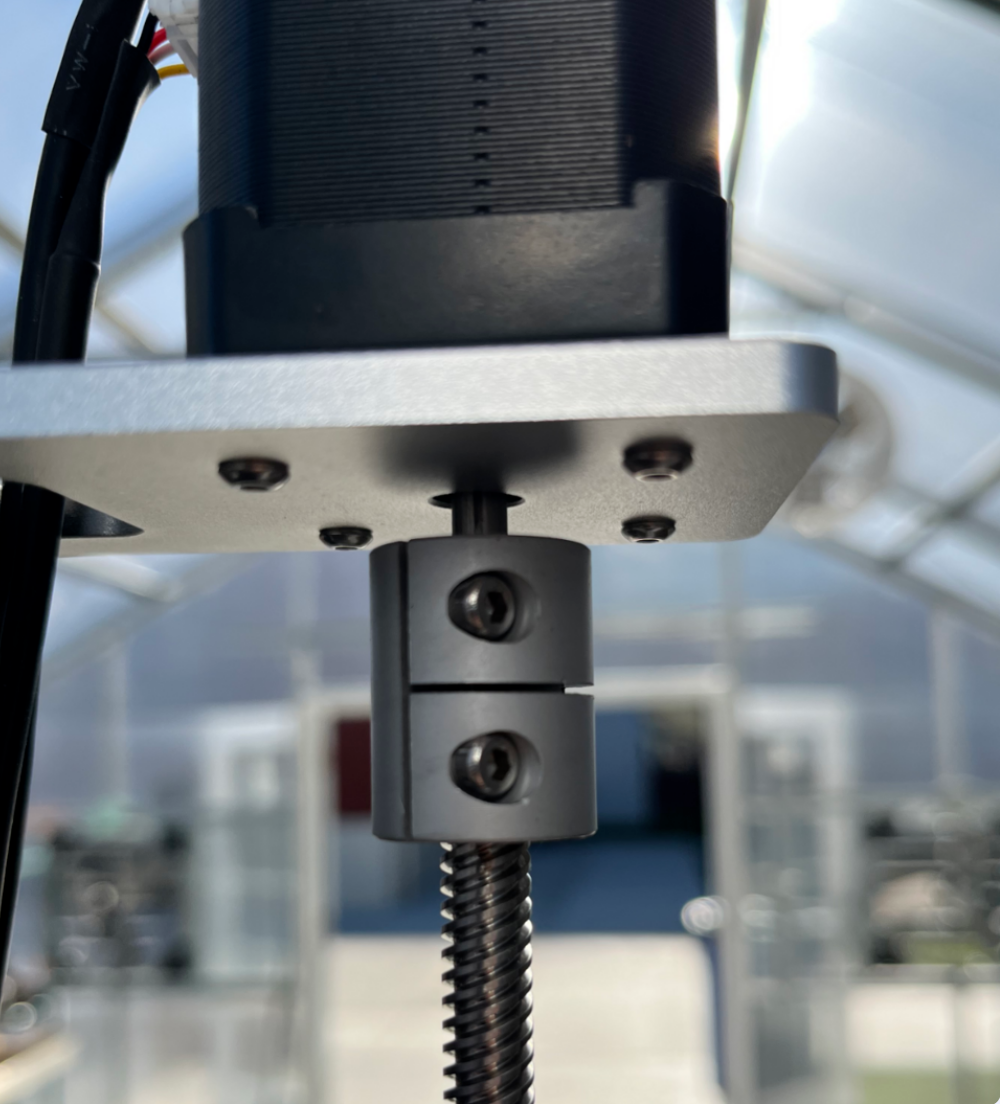

5. Check the shaft coupler for slipping

The aluminum shaft coupler connects the Z-axis motor to the leadscrew to allow FarmBot to move in the Z direction up and down depending on the rotation of the motor.

Check to make sure that the shaft coupler is not slipping as it transfers rotational power from the motor to the leadscrew. If there is slipping, tighten the screws on the coupler. You may optionally use blue Loctite to prevent the screws from loosening over time.