Cross-Slide + Z-Axis

Pre-assembly instructions for the FarmBot Express and Express XL cross-slide + z-axis

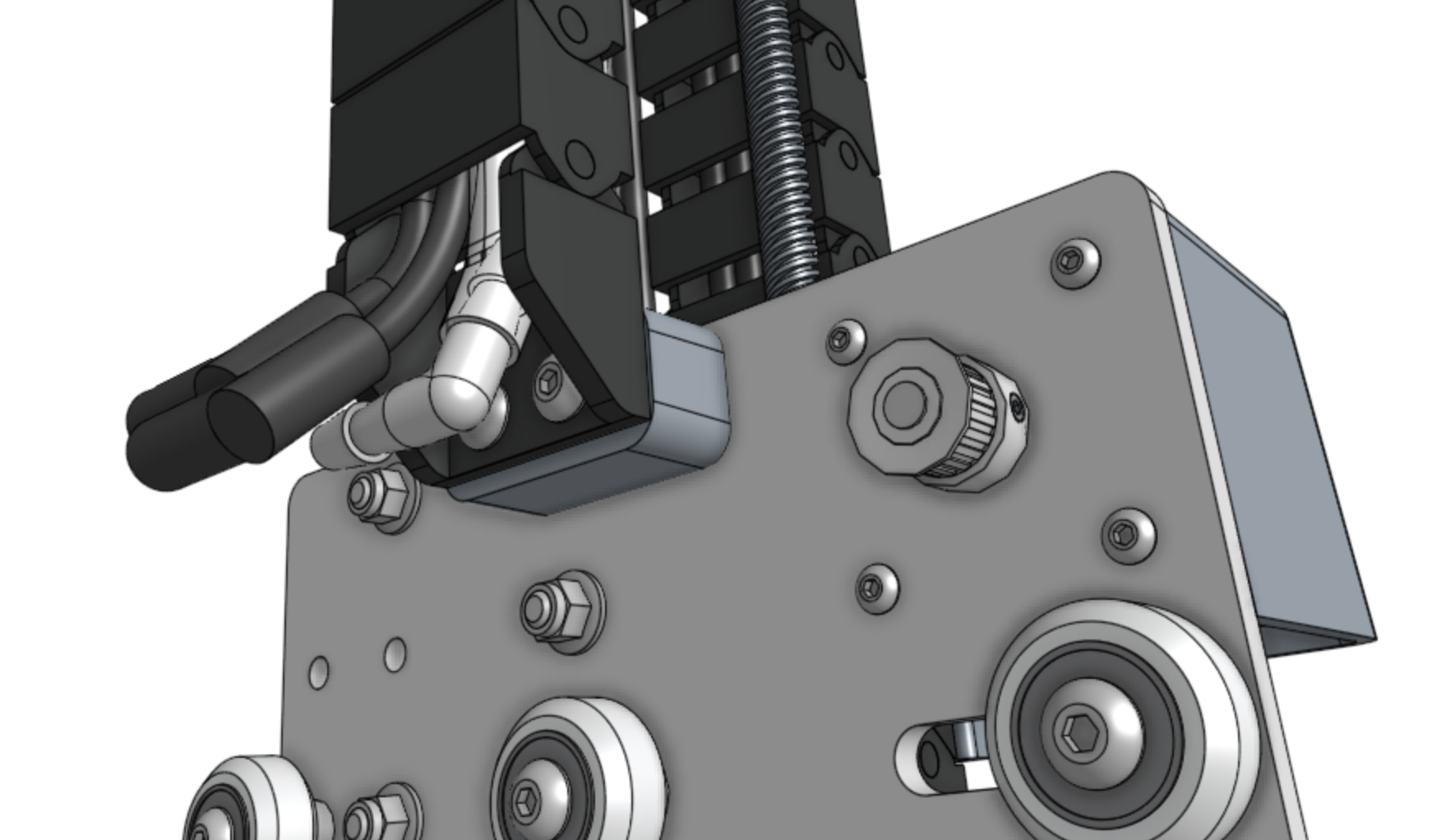

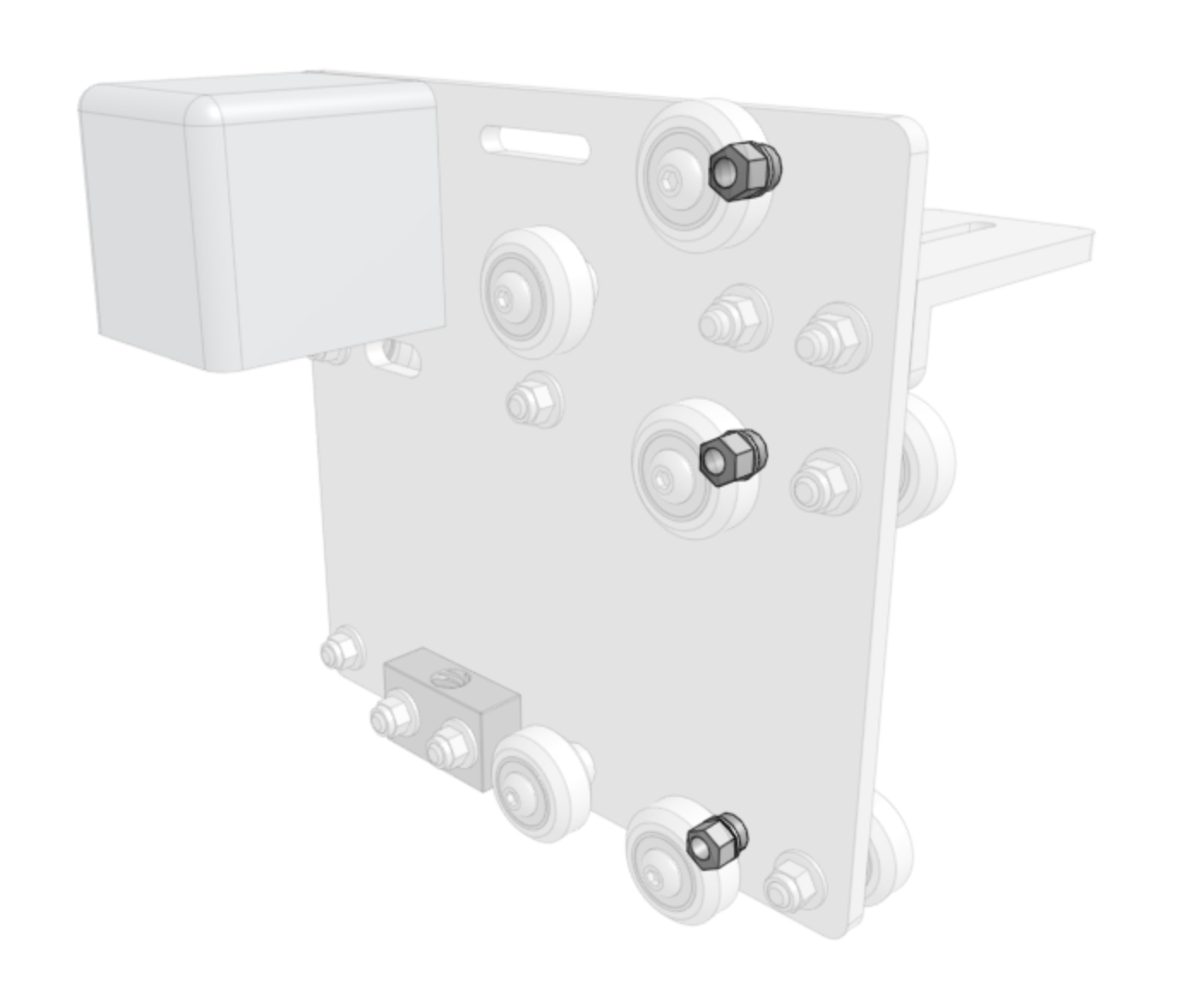

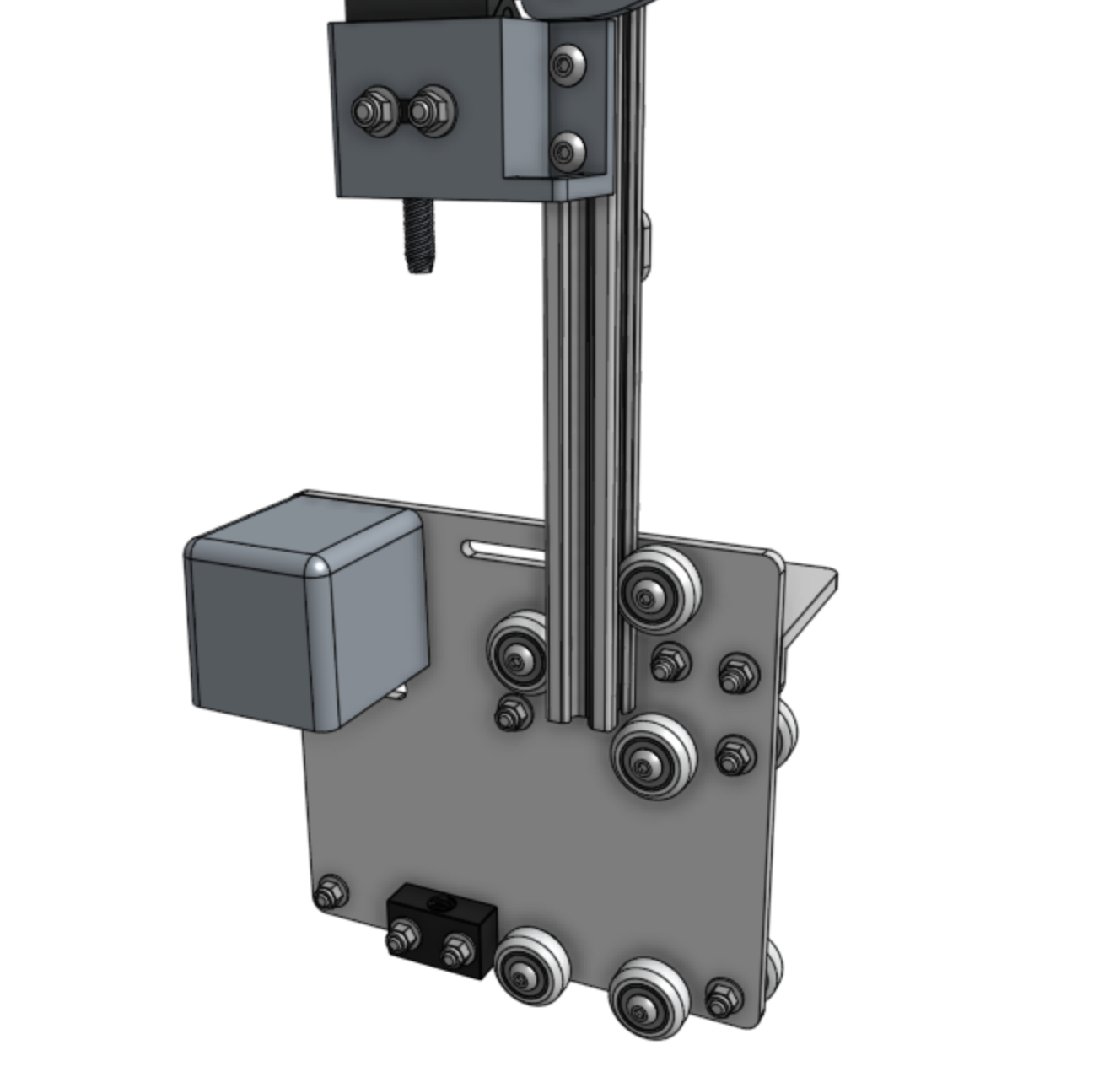

Step 1: Adjust the eccentric spacers for maximum clearance

Using the 8mm wrench, rotate the three eccentric spacers shown in the image below such that the 6mm text on the spacer is pointing towards the right side of the cross-slide plate.

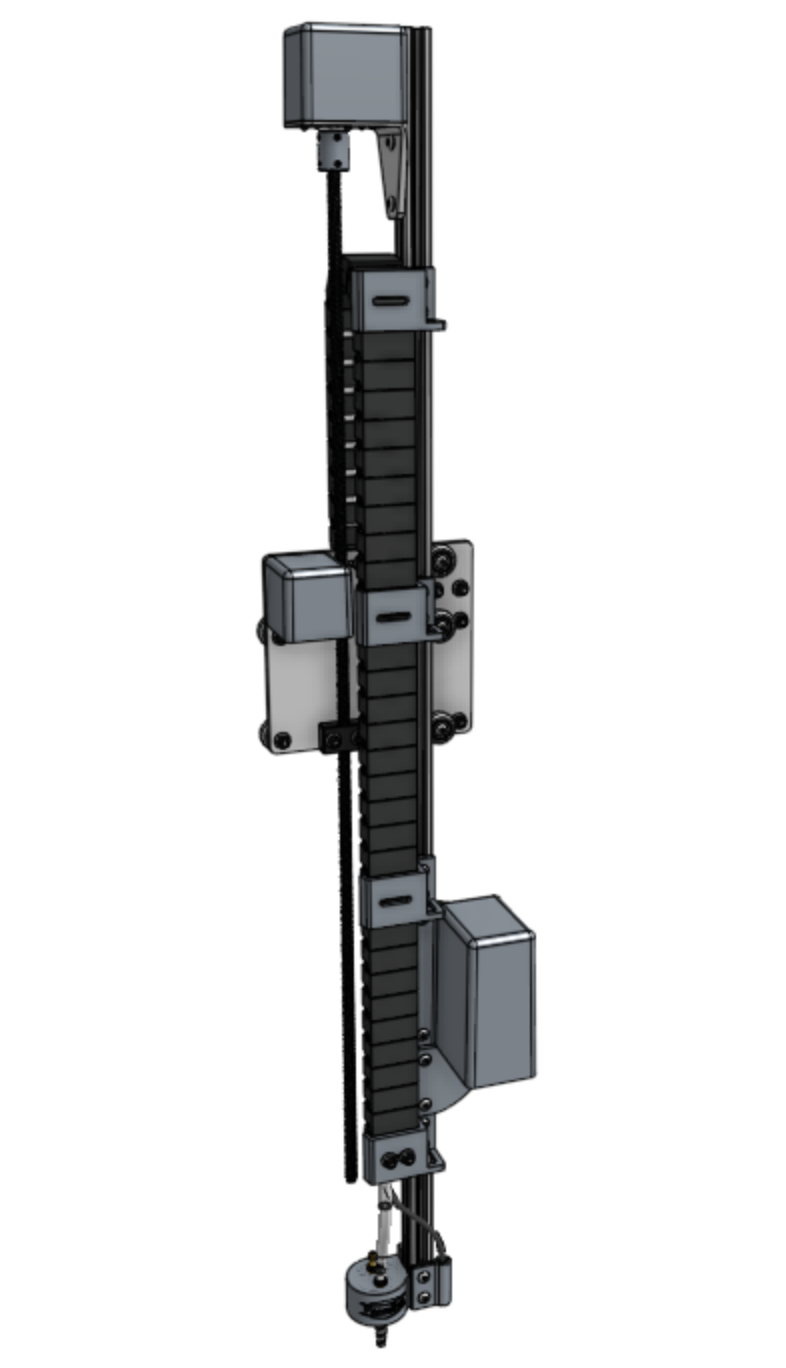

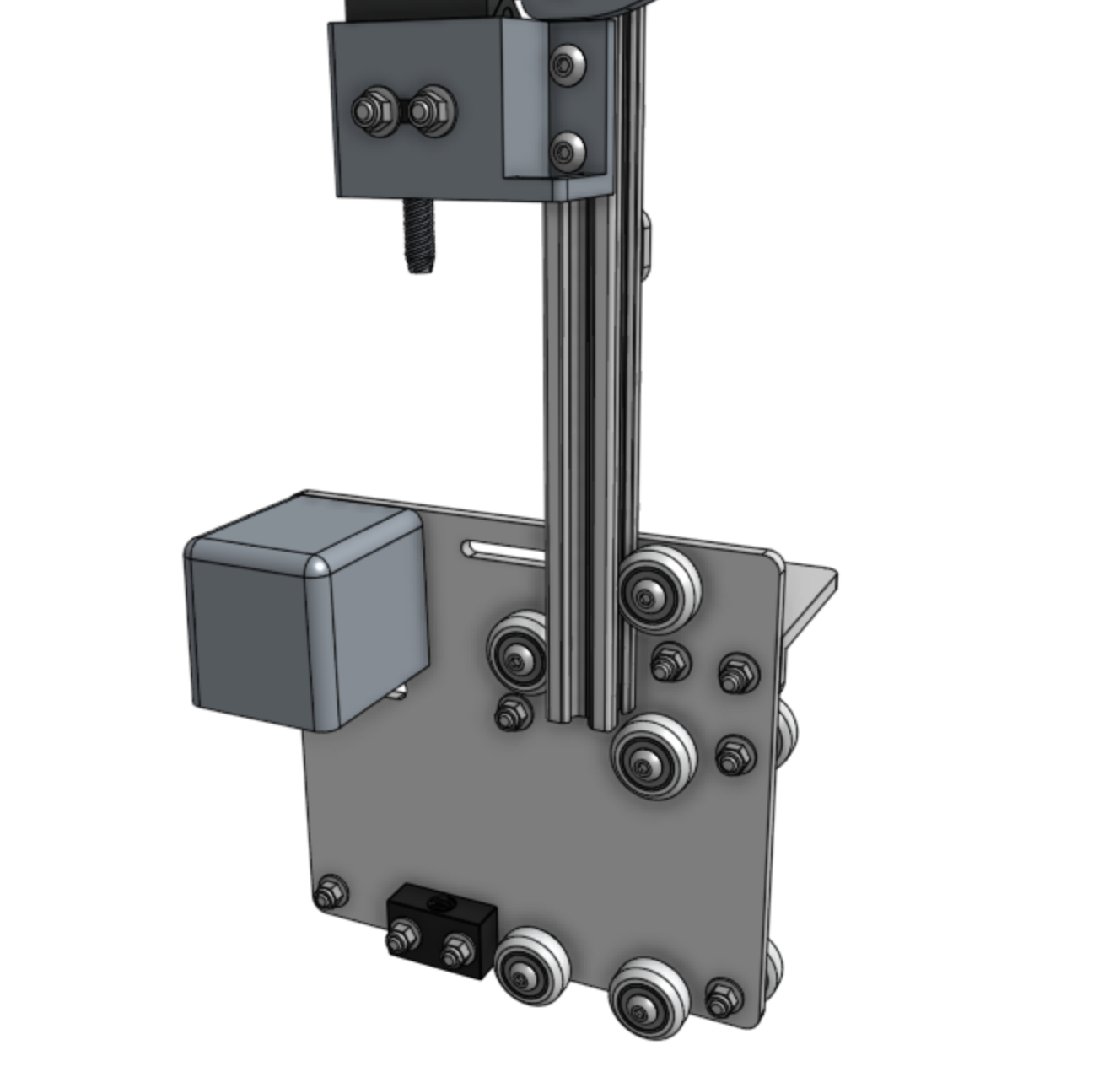

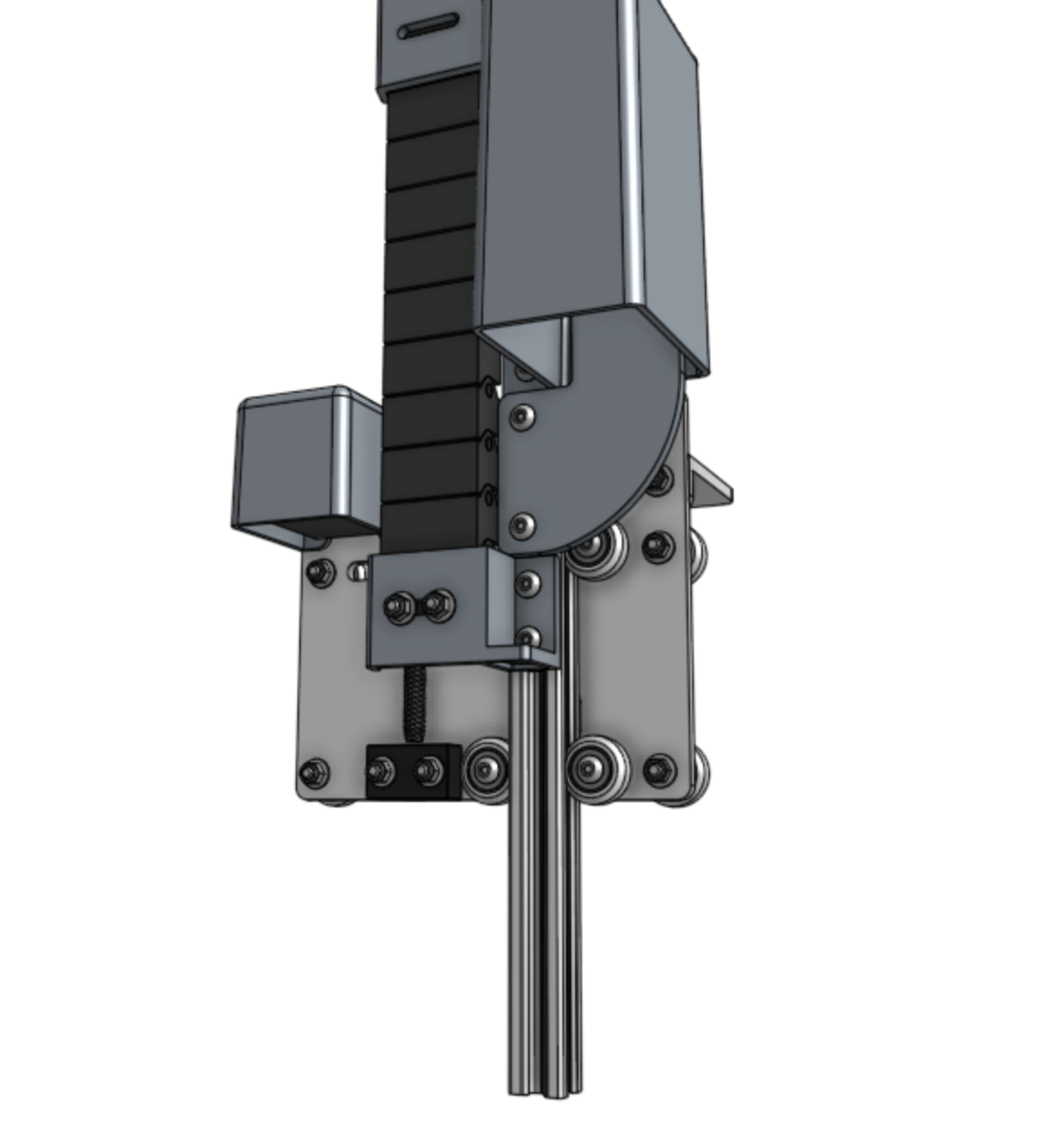

Step 2: Slide the z-axis into the cross-slide

Slide the z-axis sub-assembly into the cross-slide until the leadscrew touches the leadscrew block.

Do not force the extrusion into the cross-slide

The extrusion should be able to slide into the cross-slide easily. If you encounter resistance, DO NOT FORCE IT. If the extrusion does not slide in, ensure the eccentric spacers are adjusted according to the instructions in step 1. If the extrusion still does not slide in, loosen the flange locknuts for the two v-wheels with normal spacers, push those v-wheels towards the motor and retighten. There should now be enough clearance between the v-wheels for the extrusion to slide into the cross-slide.

Step 3: Adjust the eccentric spacers

Using the 8mm wrench, finely adjust the same three eccentric spacers from before to eliminate any wobble the extrusion has when sliding up and down. Do not overtighten the eccentric spacers. The idea here is to achieve a smooth, wobble-free movement, but not introduce unnecessary friction and resistance into the system.

Once the eccentric spacers are adjusted properly, move onto the next step.

Step 4: Turn the leadscrew by hand

Turn the leadscrew by hand to screw it into the leadscrew block. Continue until the cross-slide is positioned roughly in the middle of the z-axis extrusion.

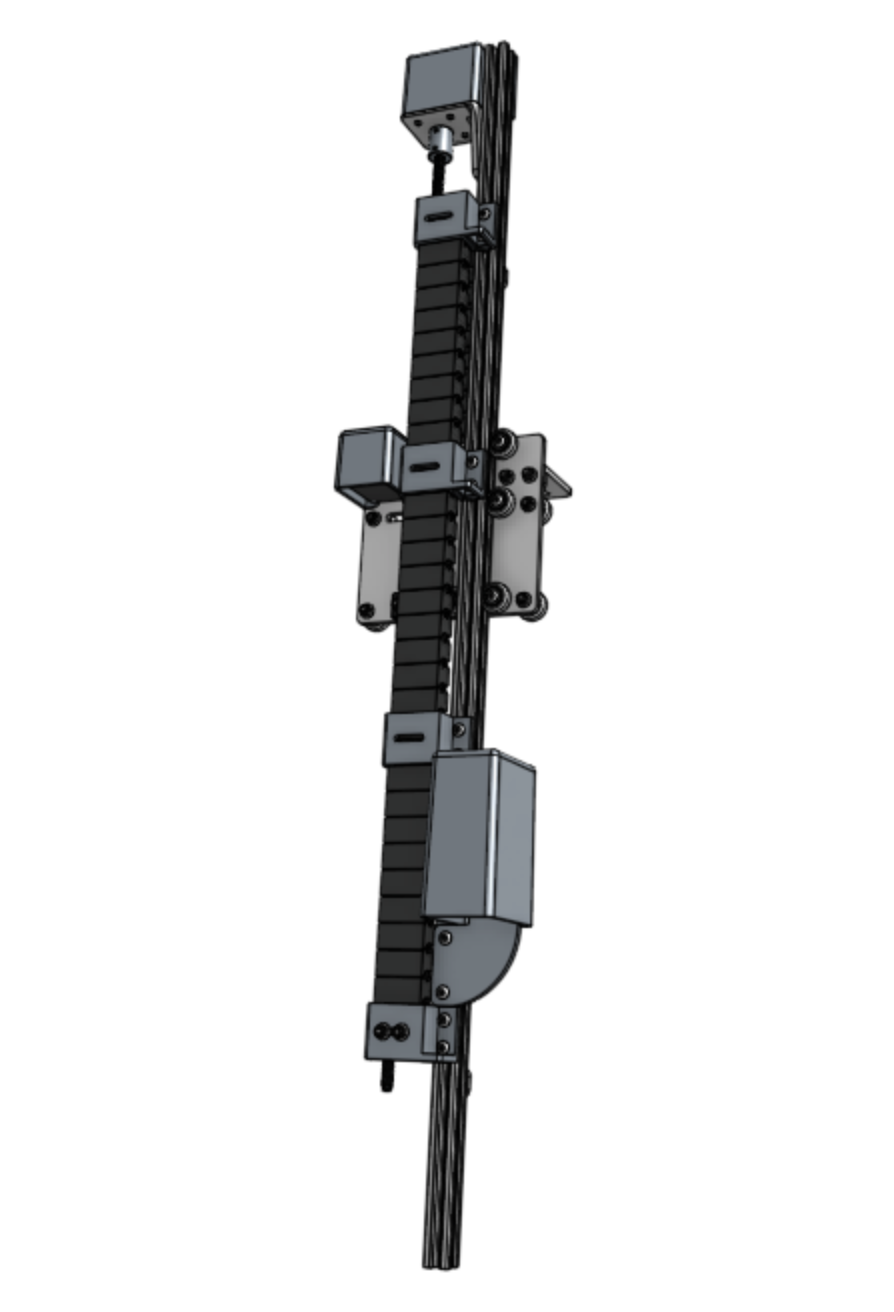

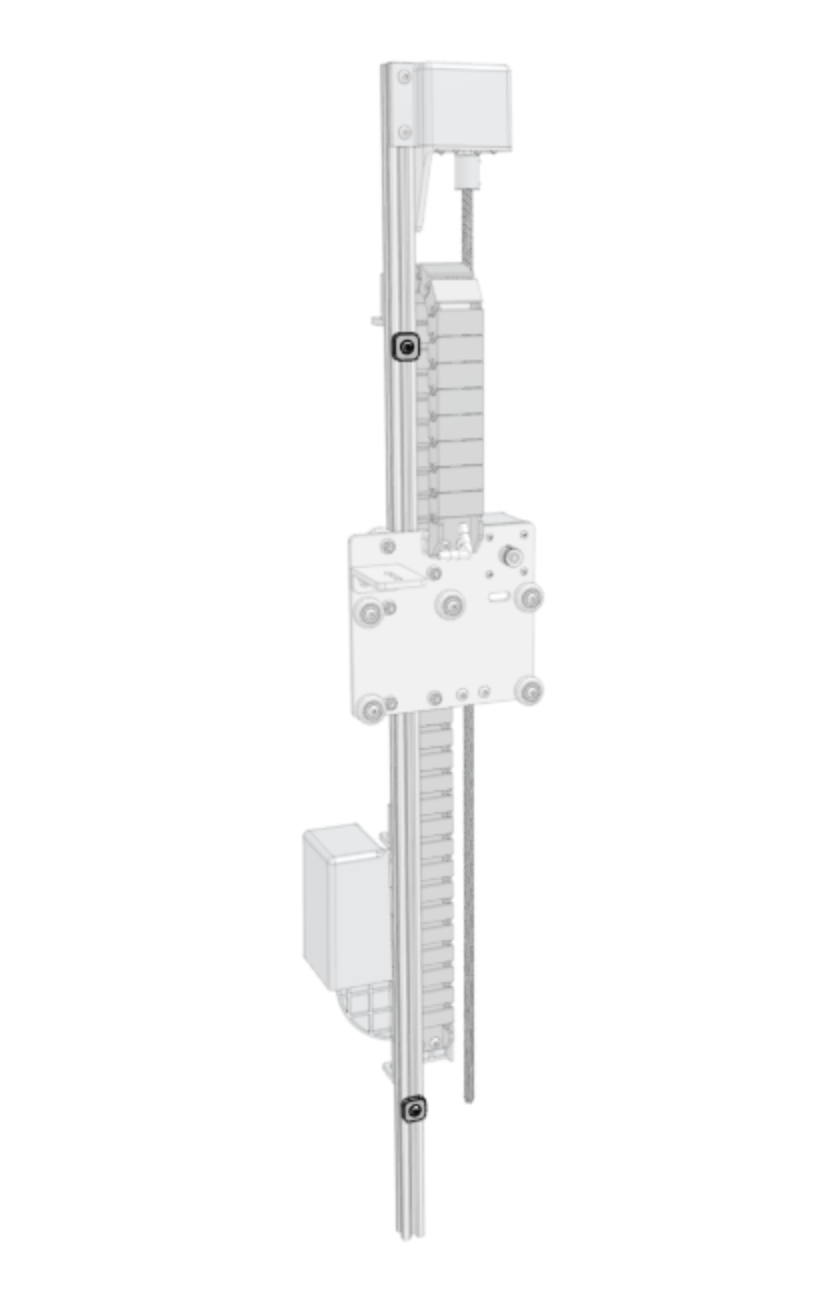

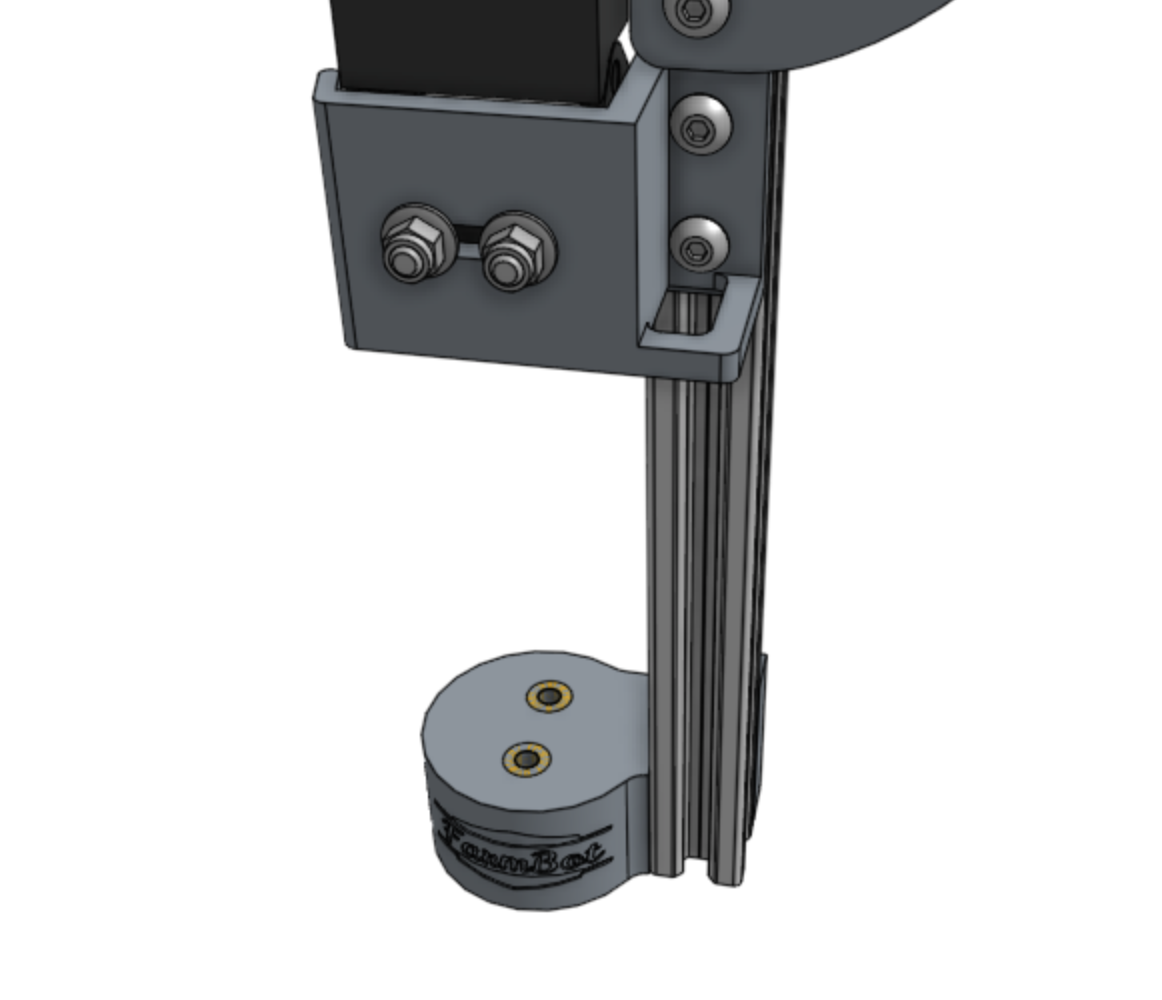

Step 5: Attach the z-axis hardstops

Attach the two z-axis hardstops to the back side of the z-axis extrusion using M5 x 10mm screws and 10mm nut bars. The lower hardstop should be positioned 120mm above the bottom of the extrusion. The upper hardstop should be positioned 200mm below the top of the extrusion.

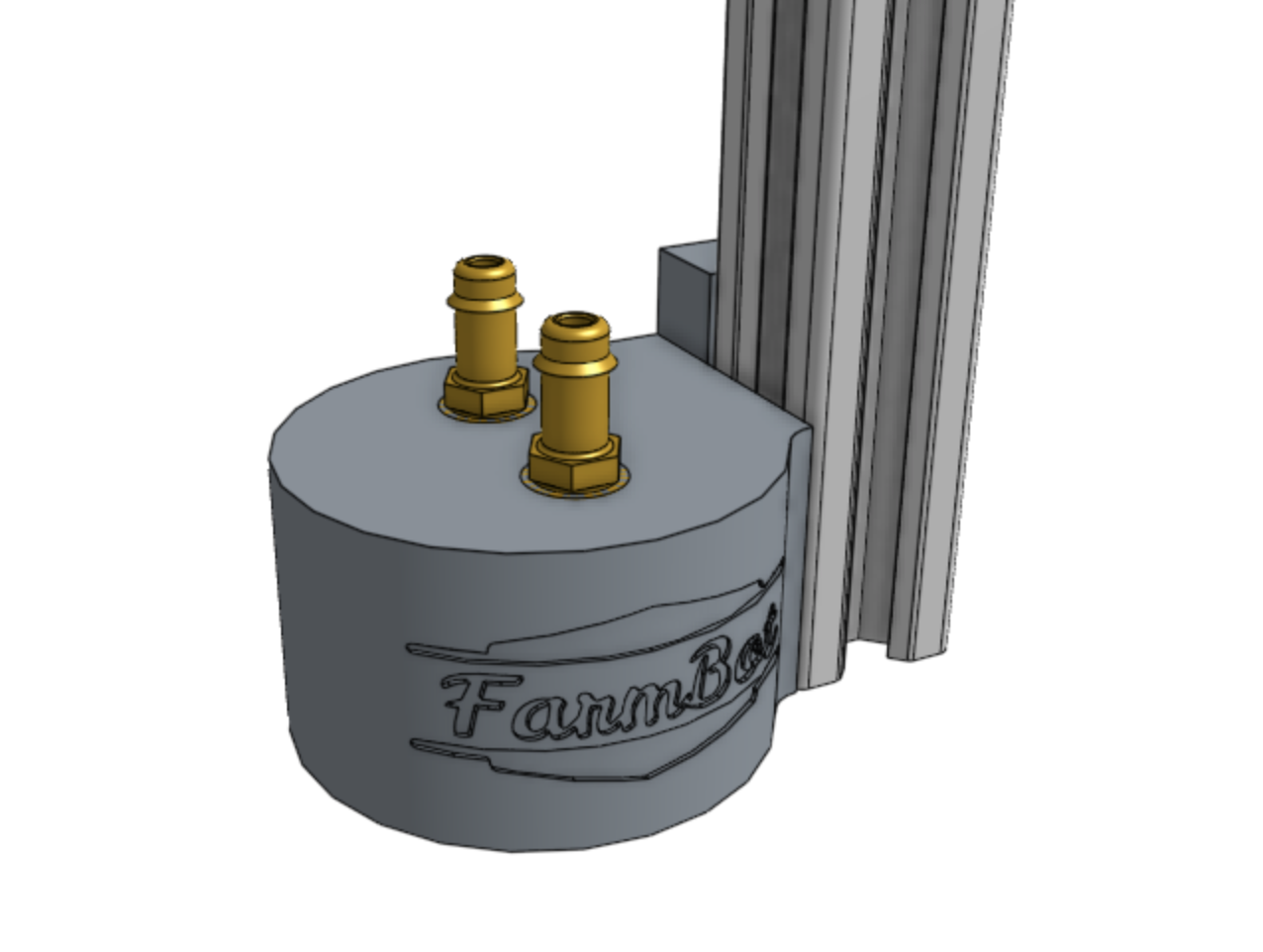

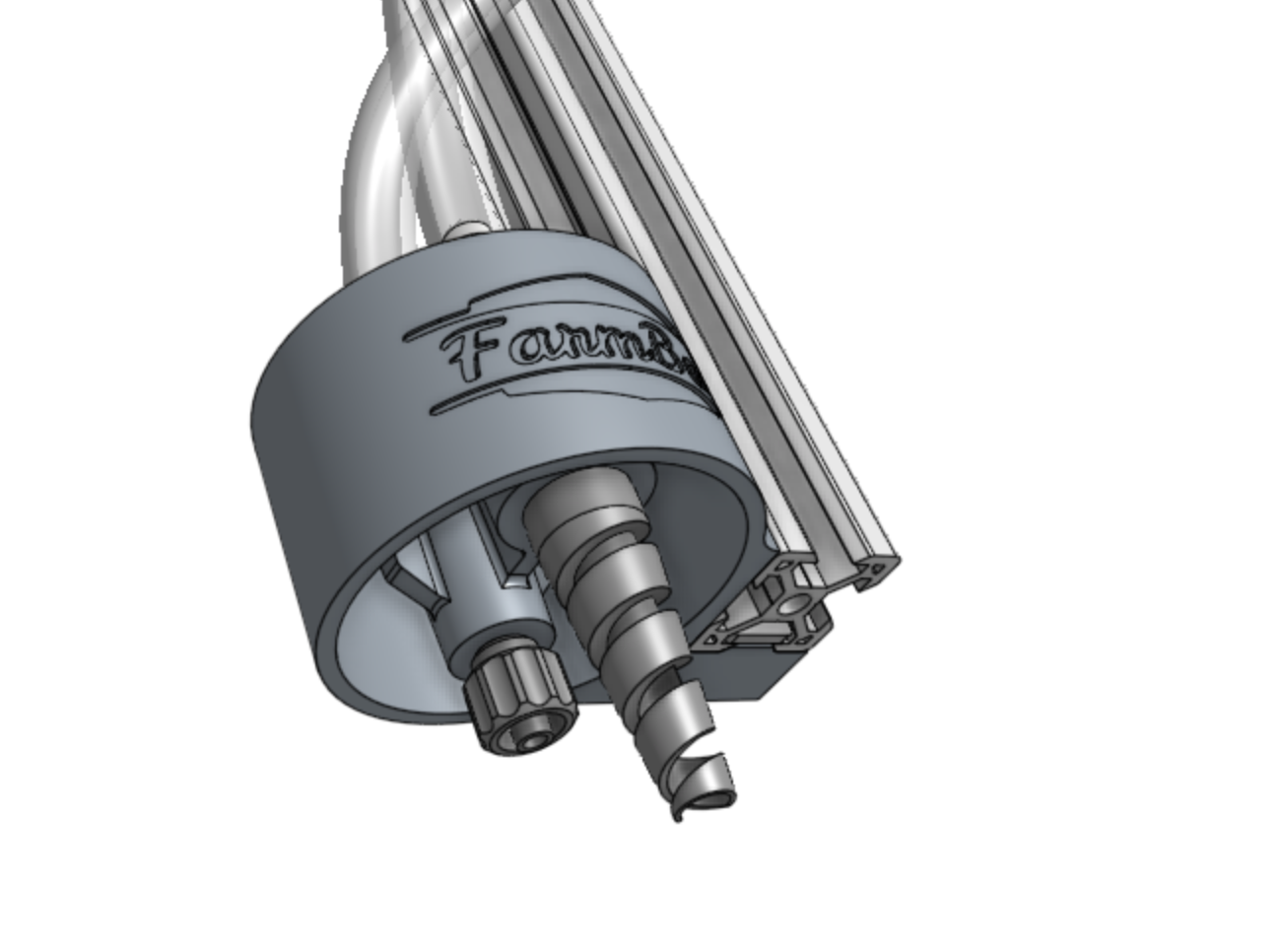

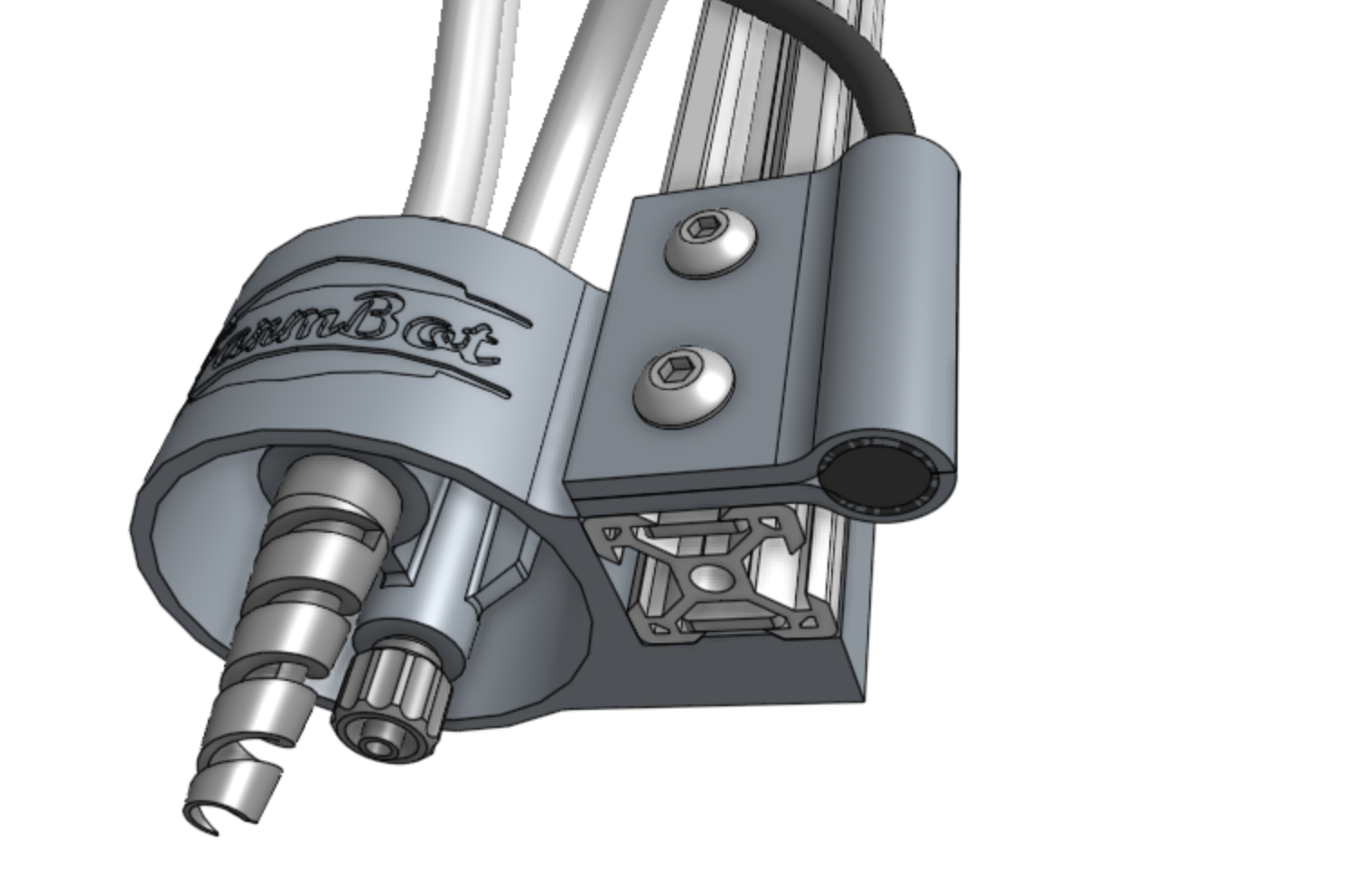

Step 6: Mount the 3-in-1 tool head

Attach the 3-in-1 tool head to the z-axis extrusion using two M5 x 16mm screws and one 40mm nut bar. The bottom of the tool head should be flush with the bottom of the extrusion.

Screw the two barbs into the top of the 3-in-1 tool head.

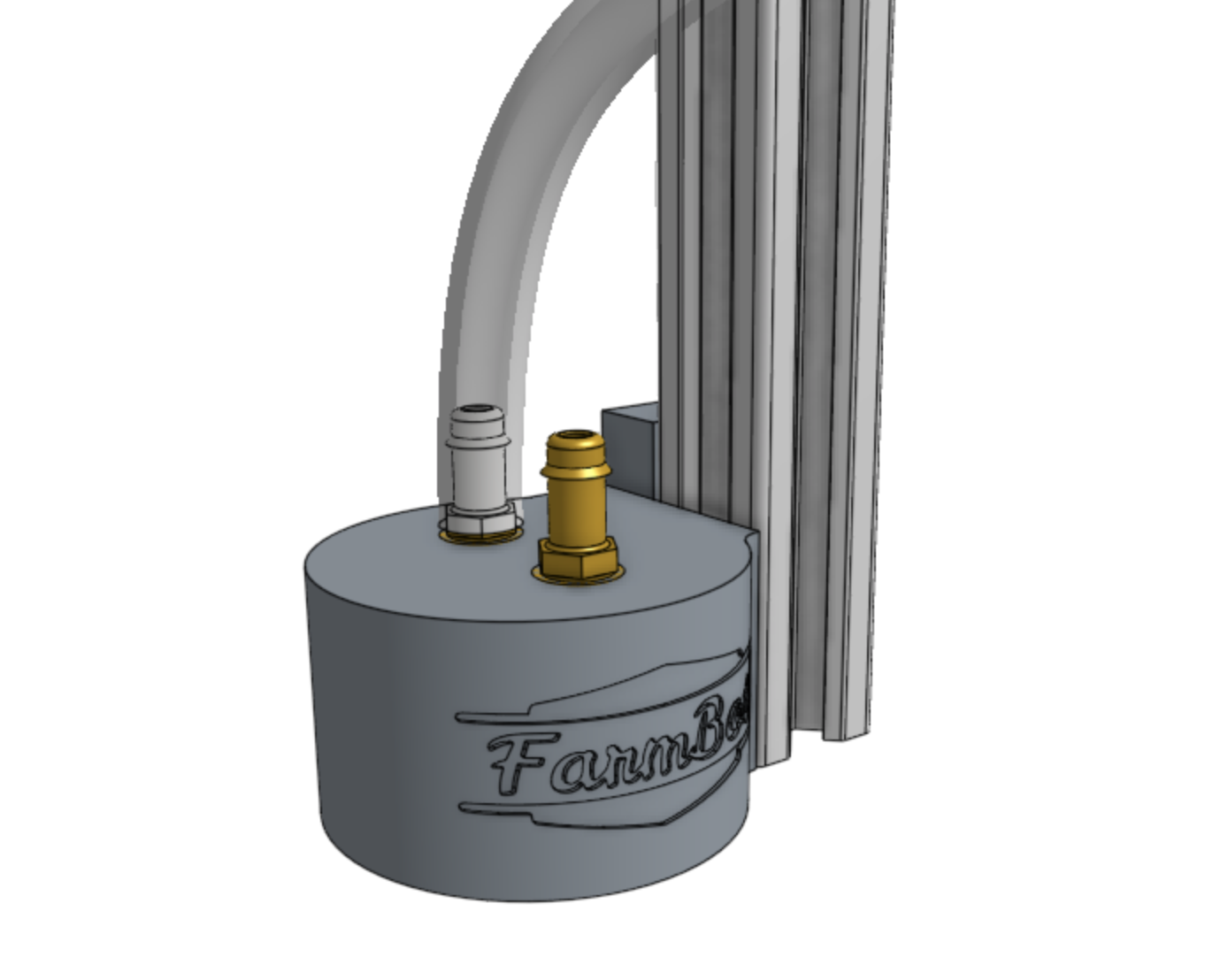

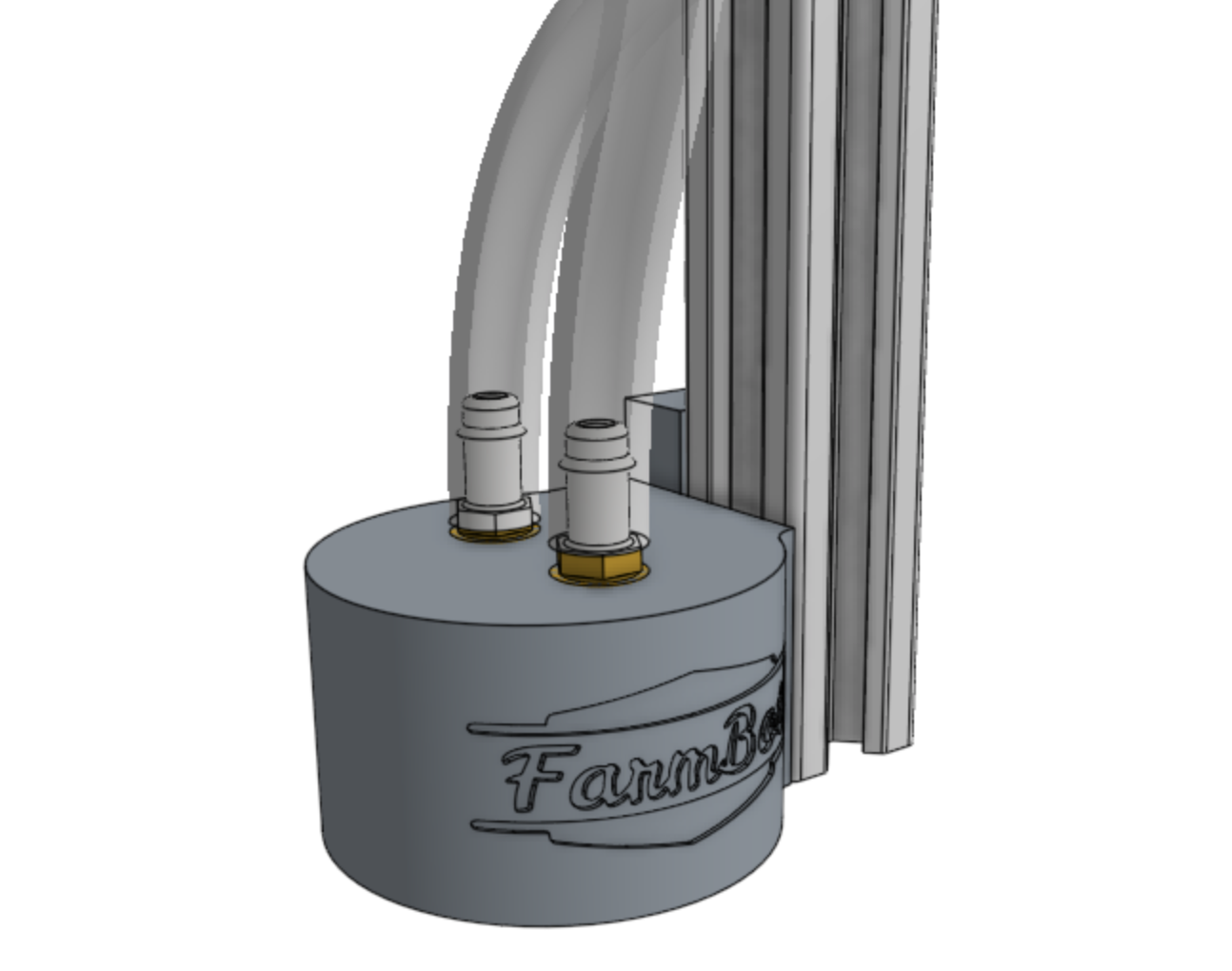

Press the vacuum tube onto the barb that is farthest from the FarmBot logo.

Press the water tube onto the barb that is closest to the FarmBot logo.

Screw the luer lock adapter and spiral spray nozzle into the bottom of the 3-in-1 tool head.

Step 7: Attach the camera

Mount the camera to the z-axis extrusion using two camera mount halves, two M5 x 10mm screws, and one 40mm nut bar.

Step 8: Attach the cable carrier

Attach the z-axis cable carrier to the cross-slide plate using two M5 x 30mm screws, two M5 flange locknuts, and the cable carrier spacer block.